Mine and slope automation monitoring case

Release time:

2024-03-25

Overview

With the development of the mining industry, the mining area is getting larger and larger, the mining depth is getting deeper and deeper, and the automatic monitoring of the displacement of the rock and soil around the pit will be getting higher and higher. In addition, the soil slippage and collapse accidents have occurred frequently in recent years, so the necessity of monitoring can be imagined! This is also a necessary condition for the safety norms of mining enterprises.

The automatic safety monitoring of rock and soil can effectively monitor the stress deformation of rock and soil around the mine, reasonably arrange the sensor burial scheme according to the stress size, collect regularly, watch, sort out and analyze the data in time, and make corresponding countermeasures through the analysis of data and statements, so as to predict the risks in advance and reduce the accident rate.

Monitoring content

According to the geotechnical characteristics and environmental structure of the mine and slope, different monitoring contents are selected, such as vertical and lateral pressure of soil, deep horizontal displacement of soil, surface displacement settlement, rock mass crack, seepage pressure, internal stress and other automatic monitoring contents, and there are dump, tailings pond, pit fault and internal formwork of well workers and mines in the region.

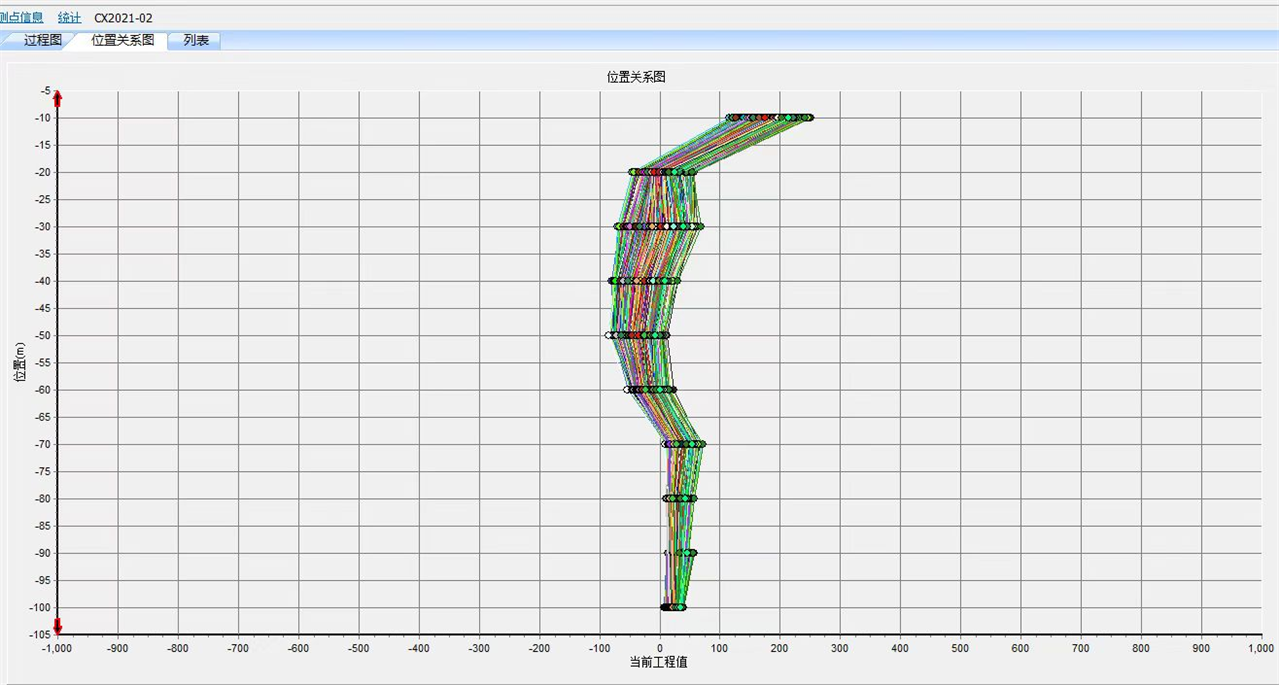

Automatic Monitoring of Deep Horizontal Displacement, Earth Pressure and Seepage Pressure in Maanshan Open-pit Iron Mine

Products used: type fixed inclinometer, vibrating wire earth pressure meter, vibrating wire osmotic pressure meter, inclinometer tube (accessories)

Project Background

This area is a corner dump and it is necessary to monitor the pressure of the dump on the rock mass.

Construction

The pit fault is divided into 6 sections -24 to 36. Each section is divided into vertical drilling and installation of inclinometer. The inclinometer is made of ABS material, which has the advantages of high toughness and light weight. After the inclinometer is lowered, fine sand is backfilled. After completion, the osmometer is lowered to the bottom of the hole and then a fixed measuring protocol is installed. The signal transmission cable is led to the position of the automatic collector and connected.

Due to the increasing amount of soil discharged in the dump, it is necessary to monitor the pressure of the dump on the rock wall, that is, the lateral pressure of the rock wall. First, the base is smashed into the inside of the rock layer, then the earth pressure gauge is installed on the base, and the signal transmission cable is led to the automatic acquisition to be connected.

After the on-site hardware is installed, the observation platform is installed on the host of the observation room and can be docked with the unit platform.

Key words:

Learn more about industry dynamics